Giới thiệu máy nghiền thủy lực quay dòng SDG

Thích hợp để nghiền các loại quặng và đá có độ cứng trung bình, thiết bị sử dụng cơ cấu truyền động thủy lực, có thể điều chỉnh kích thước cửa xả nhanh chóng, thuận tiện điều chỉnh mạch nghiền để đạt được sản lượng cân bằng, giúp sản xuất máy nghiền đạt hiệu quả tốt nhất.

Ưu điểm của máy nghiền thủy lực dòng SDG

Độ mài mòn thấp trên lớp lót

Năng lực sản xuất mạnh mẽ

Vết mòn nhỏ trên tường bị vỡ

Tốc độ hoạt động cao

| Người mẫu | Mục tiêu phát triển 4265 | SDG5065 | SDG5475 | SDG6275 | SDG6089 | SDG7089 | SDG60110 | SDG72110 |

| Công suất động cơ | 450kW | 500kW | 560kW | 630kW | 750kW | 900kW | 1400kW | 1600kW |

| Năng suất | 2000t/giờ | 2500th | 3300th | 3500th | 4500th | 4800th | 7000th | 8000th |

Danh sách thông số kỹ thuật máy nghiền quay dòng SDG

| Người mẫu | Cổng xả | Giá trị tối thiểu | Giá trị tối đa | Cổng nạp | Đường kính trục chính | Tốc độ trục truyền động | Động cơ dẫn động của nón nghiền | Tổng trọng lượng của thân máy chính | trọng lượng của trục chính | |

| 1 | Mục tiêu phát triển 4265 | 140mm | 175mm | 42''(1067mm) | 65''(1650mm) | 595RPM | 400/450kW 595 vòng/phút | 120t | 23t | |

| 2 | SDG5065 | 150mm | 175mm | 50''(1270mm) | 65''(1650mm) | 595RPM | 400/450kW 595 vòng/phút | 145t | 28t | |

| 3 | SDG5475 | 150mm | 200mm | 54''(1370mm) | 75''(1905mm) | 595RPM | 500/600kW 595 vòng/phút | 242t/259t | 38t | |

| 4 | SDG6275 | 150mm | 200mm | 62''(1575mm) | 75''(1905mm) | 595RPM | 500/600kW 595 vòng/phút | 299t | 42t | |

| 5 | SDG6089 | 165mm | 230mm | 60''(1525mm) | 89''(2260mm) | 595RPM | 630/750kW 595RPM | 399t/419t | 66t |

Danh sách năng lực sản xuất máy nghiền quay dòng SDG

| CHÚNG TA | Sản lượng (t/h) | |||||

| Mục tiêu phát triển 4265 | SDG5065 | SDG5475 | SDG6275 | SDG6089 | ||

| 1 | 125mm | |||||

| 2 | 140mm | 2010 | ||||

| 3 | 150mm | 2340 | 2400 | 2890 | 2890 | |

| 4 | 165mm | 2520 | 2780 | 2990 | 3620 | |

| 5 | 175mm | 2870 | 2940 | 3150 | 3820 | 4200 |

| 6 | 190mm | 3090* | 3160* | 3340 | 4210 | 4540 |

| 7 | 200mm | 3490 | 4330 | 5300 | ||

| 8 | 215mm | 3700* | 4540* | 5530 | ||

| 9 | 230mm | 5810 | ||||

| 10 | 240mm | 6100* | ||||

| 11 | 250mm | 6430* | ||||

Note: The above capacity is based on the following assumptions: 10% of the feed passes 80% of the feed opening, 80% of the feed passes 60% of the feed opening, and 50% passes a sieve size that is 10% of the topsize. The capacities are for feed materials with a bulk density of 1.6 metric tons per cubic meter.

All capacity values are calculated at the maximum eccentricity of each device, and all capacities are subject to different applications. Factors to consider when determining total crushing capacity include: material characteristics, feed particle size, material distribution, work index, water content and feeding method. Please consult Shunda engineers to determine your processing capacity requirements.

*The gray table is the processing capacity of coarse cavity liner. The product particle size distribution is coarser using this cavity type, compared with the standard cavity type.

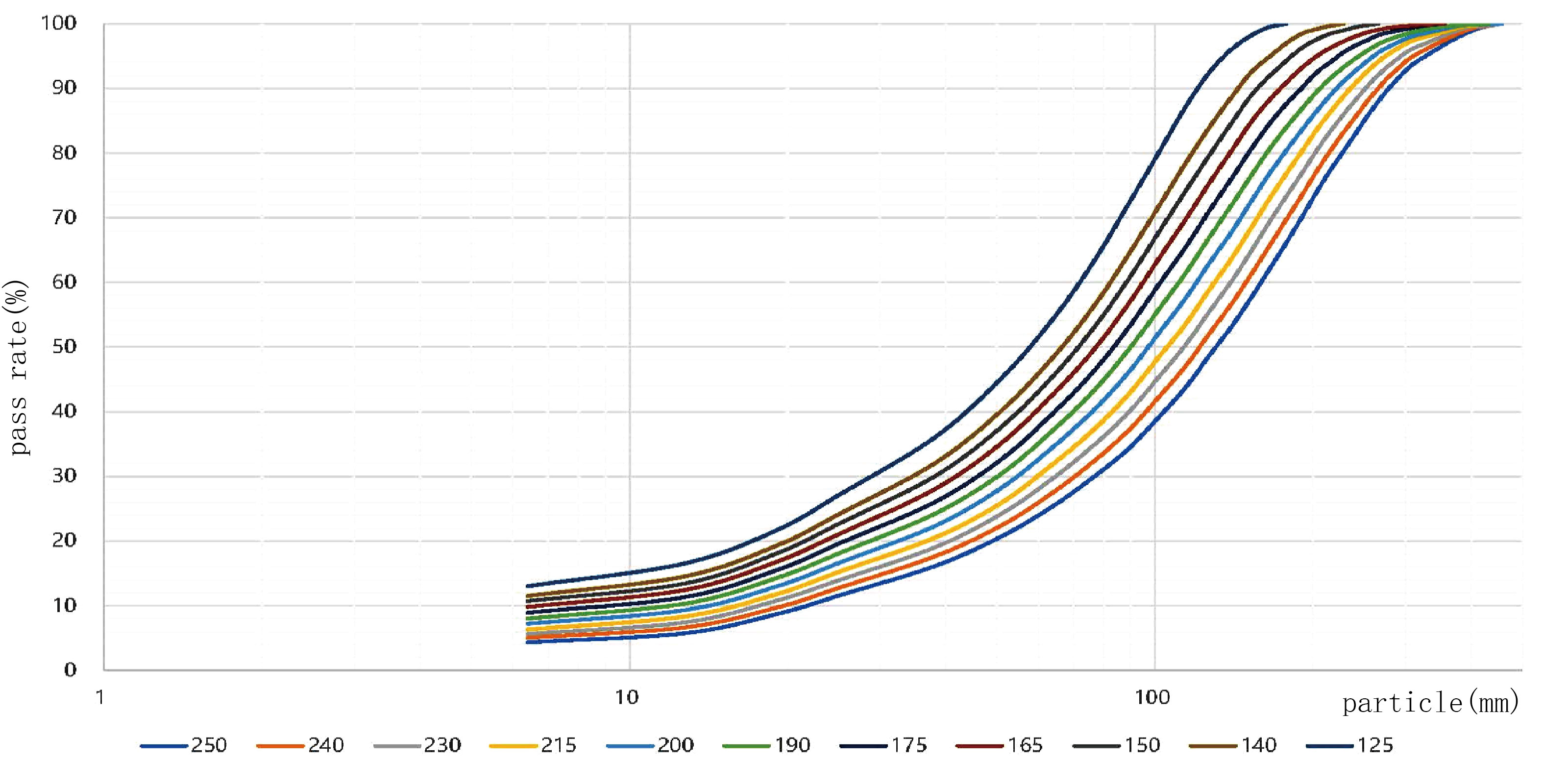

SDG Series Gyratory Crusher Particle Distribution

The particle size curve can be used as a tool for preliminary selection of SDG series gyratory crusher. The data in the table is suitable for medium-hard ore, hardness of 10-15, loose density of 1.6t/m', 100% passes 80% of the feed opening, 80% passes 60% and 50% passes a sieve size that is 10% of the topsize, open-circuit operation conditions of particle size distribution.

If the feeding condition changes, or the ore is easier (more difficult) to crush, the product particle size changes accordingly. For detailed particle size distribution, please consult our engineer.

The following factors can increase the production capacity and performance of the crusher

1. Appropriate proportion of feed particle size.

2. The proper selection of eccentricity.

3. Operate with full cavity capacity.

4. Evenly feeding on both side.

5. Automatic control.

6. Optimization on cavity shape.

The following factors will reduce the production capacity and performance of the crusher

1. Feeding cohesive material in the crusher.

2. Water content of the feeding material is too much.

3. The improper selection of eccentricity.

4. Operate without full cavity capacity.

5. Single sided feeding or feed segregation.

6. Feed is too hard or tenacious.

7.Crusher operating under the recommended speed.

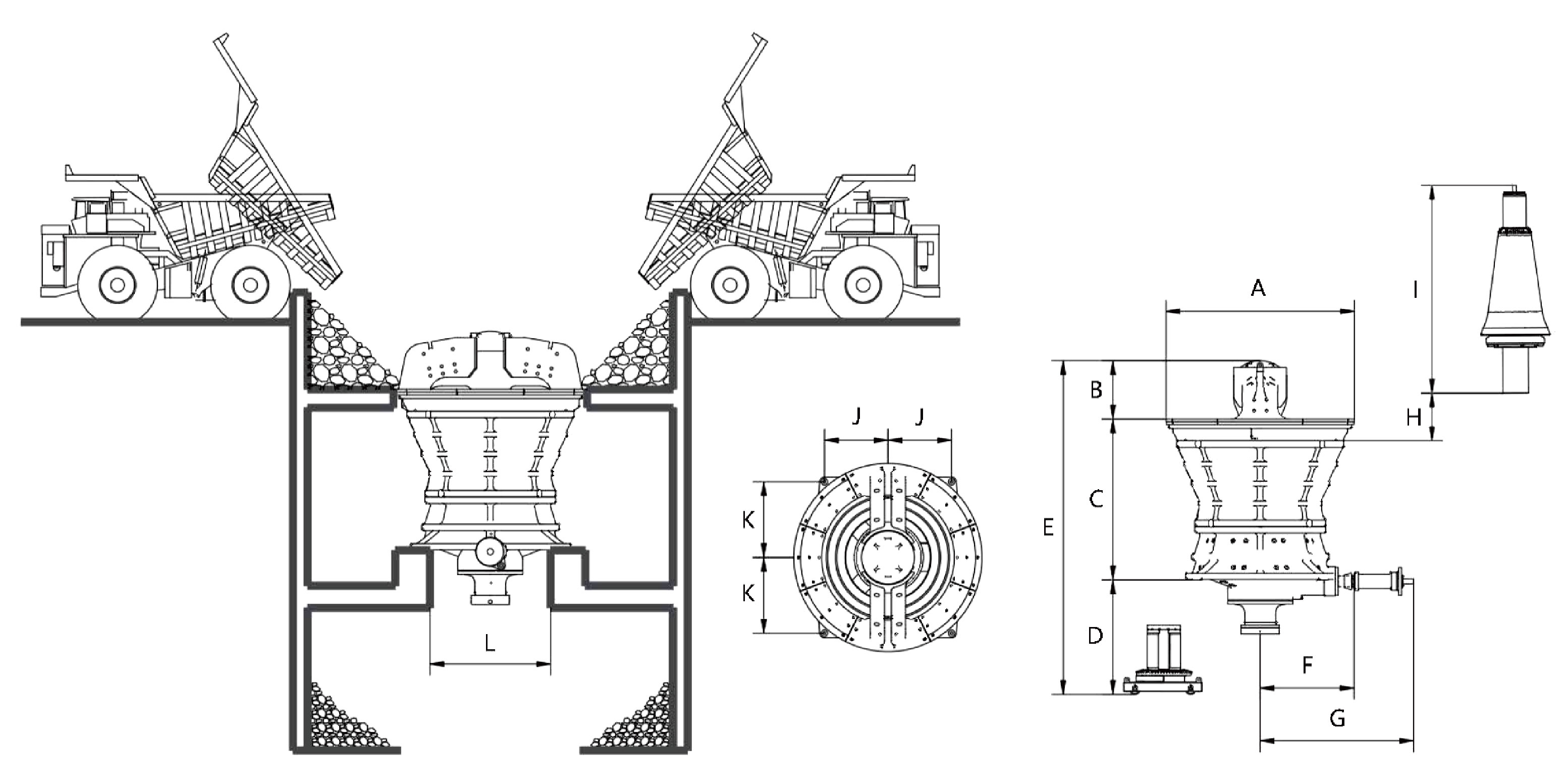

SDG Series Gyratory Crusher Space Size List

| Model | SDG4265 | SDG5065 | SDG5475 | SDG6275 | SDG6089 | |

| 1 | Outer diameter of feed inlet | 3940 | 4460 | 4930/5150 | 5575 | 5590/6170 |

| 2 | Feed inlet end surface to top of crossbeam | 1425 | 1510 | 1600 | 1600 | 2110 |

| 3 | Foundation to the end surface of feed inlet | 3385 | 4005 | 4350 | 5040 | 5370 |

| 4 | Space for dismantling the adjustment sleeve | 2150 | 2150 | 2500 | 2500 | 3000 |

| 5 | Minimum space for the crusher | 6900 | 7610 | 8410 | 9080 | 10470 |

| 6 | From crusher centre to drive side | 2200 | 2200 | 2460 | 2460 | 2650 |

| 7 | Space for dismantling the drive shaft bracket | 3445 | 3445 | 4045 | 4045 | 4200 |

| 8 | Space for dismantling the mainshaft | 200 | 200 | 200 | 200 | 200 |

| 9 | Mainshaft height | 4580 | 5200 | 5635 | 6185 | 6825 |

| 10 | Anchor distance in the direction of drive shaft | 1530 | 1530 | 1750 | 1750 | 1760 |

| 11 | Anchor distance that perpendicular to the drive shaft | 1670 | 1670 | 2075 | 2075 | 2420 |

| 12 | Min.diameter of discharge port | 2620 | 2620 | 3230 | 3230 | 3750 |

| 13 | Designed resting angle for the bin(°) | 45-50 | 45-50 | 45-50 | 45-50 | 45-50 |

| 14 | Minimum effective volume of discharge bin | Truck load capacity | Truck load capacity | Truck load capacity | Truck load capacity | Truck load capacity |

FAQ

Q: What is your company's business principle?

A: Our company regards quality as life and serving users as God.

Q: What is our warranty?

A: 100% brand new when leaving the factory, the seller guarantees the quality of the machine (excluding easy-to-wear parts) for one year from the date of completion of the trial run, but no more than 15 months from the date the machine leaves the factory.

Q: What is the price of this product?

A: We can give the lowest price than the market, and we will provide a quotation for any customer as soon as possible, and discounts can be given according to quantity.

Q: Service and payment terms?

A: We can accept T/T and L/C; 30% deposit, 70% balance paid before delivery, which is an international trade practice; finished product pictures will be provided to customers before delivery.